Leak detection for non-metered stub lines, laterals, and HCAs.

Autonomous & reliable detection where

traditional systems fall short.

The leak detection gap.

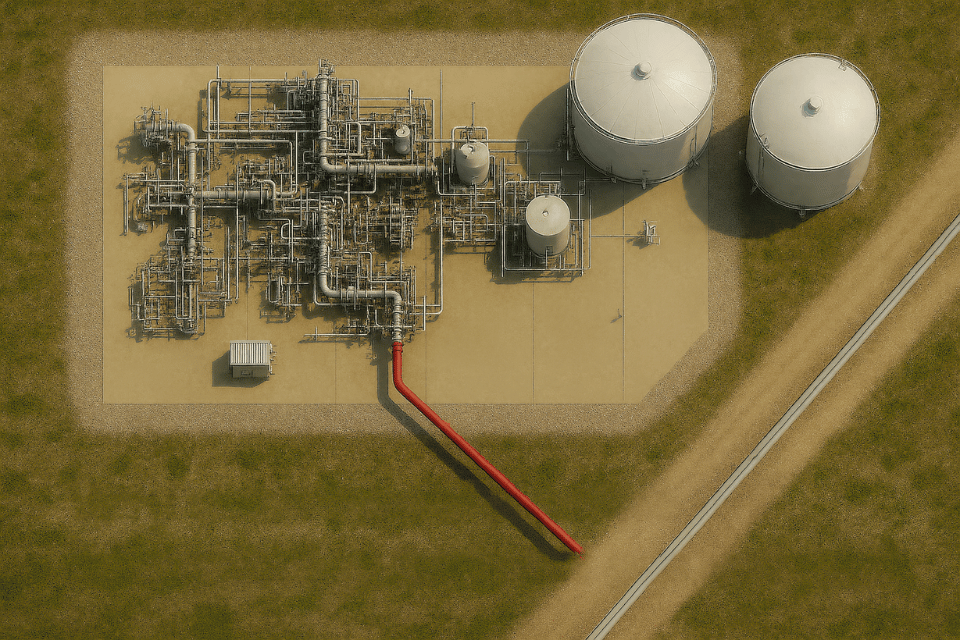

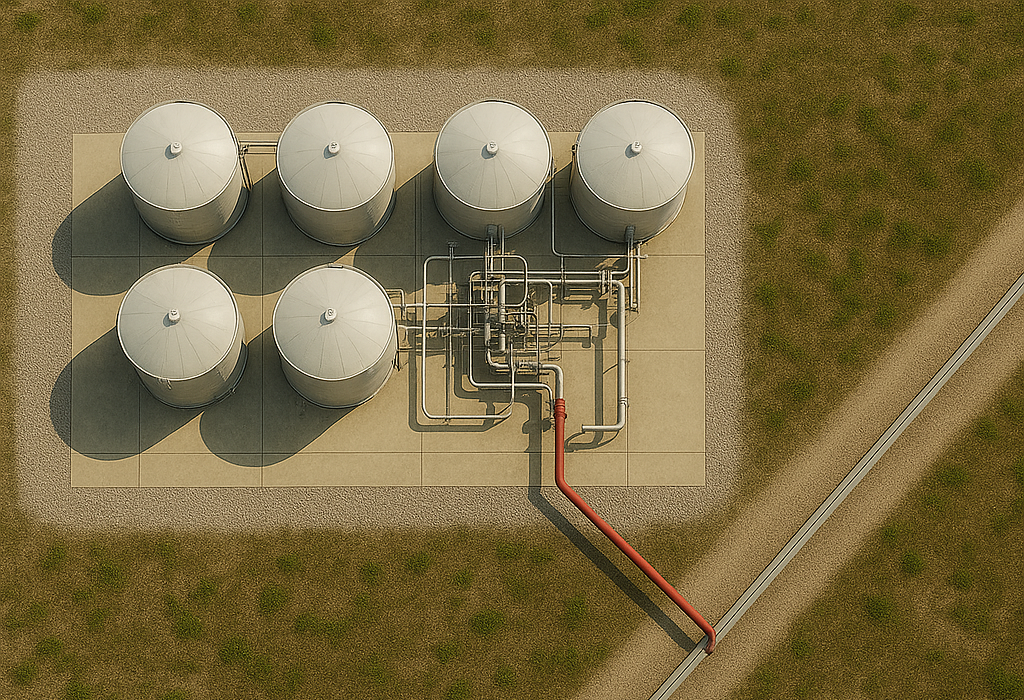

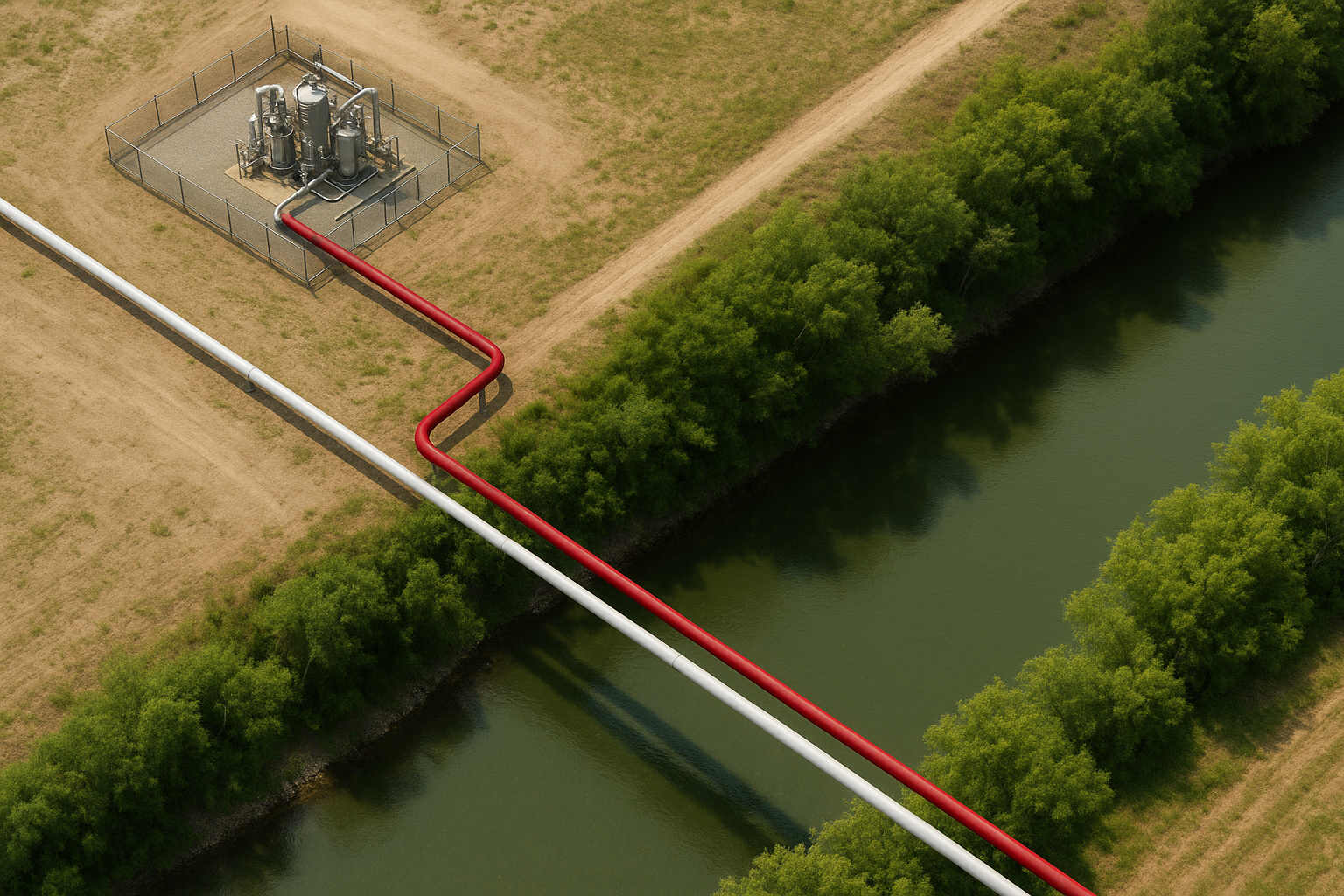

Stub lines, laterals, and river crossings are costly to meter and laterals are often outside the

operator’s full control, leaving these critical assets unprotected and exposed to risk.

Lateral Lines

Stub/transfer lines

River Crossings (HCAs)

How Pipewise closes this gap.

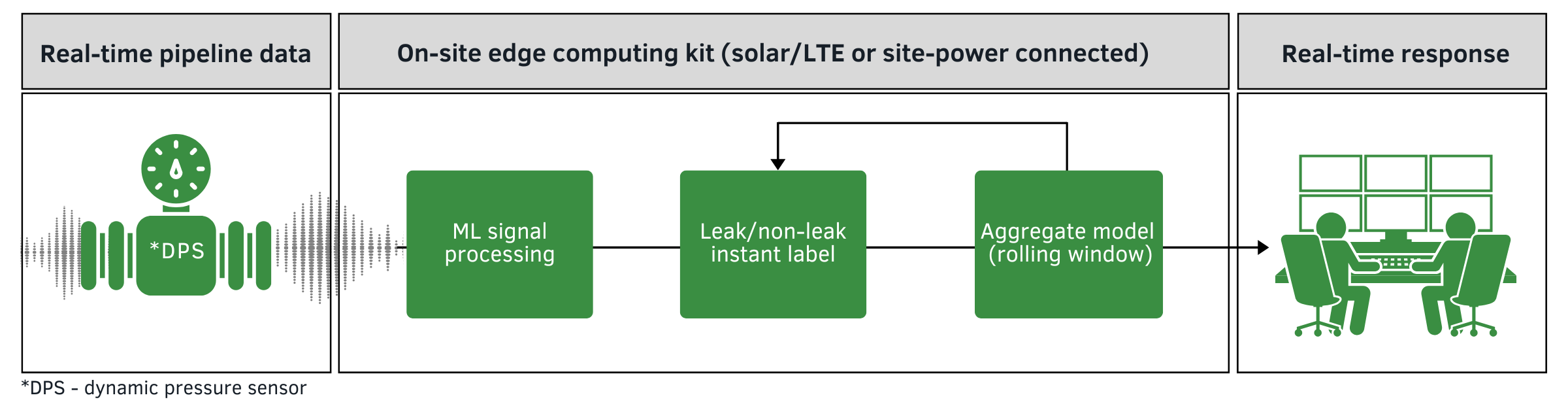

Pipewise provides a stand-alone, autonomous leak detection system built specifically for short, non-metered pipelines and high consequence areas (HCAs).

With built-in sensors, on-site edge computing, and ML detection intelligence, Pipewise delivers sensitive and reliable protection without the costly meters.

- Stand-alone unit – sensors and edge ML built in; runs autonomously or with site power.

- No meters required – works without flow instrumentation, taps, or trenching.

- Fast deployment – units installed in hours, protects immediately.

- Flexible power & connectivity – self-sufficient solar/LTE or connected to site power

- Compliance ready – aligned with API RP 1130/1175, CSA Z662, PHMSA 49 CFR 195

How it works

Pipewise listens to the pipeline, filters out noise, and classifies leaks in real time. By processing

signals locally, it delivers dependable detection where SCADA-based or CPM systems can’t

Performance you can trust.

Detection rate (flow)

0

%

Time to detection (min)

<

0

Localization from sensor (miles)

1-

0

False alarms identified

0

%

Current operational coverage & specifications.

- Optimized for water or liquid hydrocarbon pipelines.

- Optimal detection at standard industry pressures (~300-1,500 PSI/2–10 MPa) and steady flow.

- Compliance ready – API RP 1130/1175, CSA Z662, PHMSA 49 CFR 195.

Put a system to the test & close the detection gap. Only with Pipewise.

Download the overview presentation.

Fast to deploy. Flexible to operate.

Solar-powered, LTE-connected, and Class 1 Div 2 rated for the toughest environments, Pipewise

installs anywhere, runs autonomously, and connects seamlessly to your workflow.

Pole Mounted Installation

Wall Mounted Installation

A-frame Mounted Installation

Always included with every deployment.

24/7 service & support.

Continuous monitoring, tuning, andtroubleshooting from our expert team.

Online portal reporting.

Real-time system status, logs, and

resources accessible anytime.

Built-in compliance.

Aligned with PHMSA, API RP 1130, and

CSA Z662 to keep you audit-ready.

Frequently Asked Questions

How does Pipewise detect leaks without flow meters?

By using on-site dynamic pressure sensing combined with edge-based ML filtering and

classification.

What’s the detection radius of one sensor?

Typically 1-2 miles (2–3 km.) upstream and downstream depending on pipeline conditions.

How small of a leak can it detect?

Down to ~1% of flow, proven in noisy, low-pressure environments.

Does this create false alarms in noisy conditions?

No. the DPX module filters noise, and ML classification provides high precision.

Can the system run completely standalone?

Yes. We can deploy the DPX kit on-site as a stand-alone solar and LTE-enabled on an A-frame, or

it can be site-power connected.